Updated on July 17, 2023

For this private visit, we are going to a secret location, somewhere in Monaco. To the site of the Monte-Carlo Société des Bains de Mer Games Workshops, a place that is as legendary as it is confidential. Here, some ten passionate experts work. Their mission: to make, maintain and check the facilities at the Casino de Monte-Carlo and at the Casino Café de Paris. Jérôme Tachoires, who leads the workshops, welcomes us into this special department and fills us in on its history.

# The Casino de Monte-Carlo: 160 years of history!

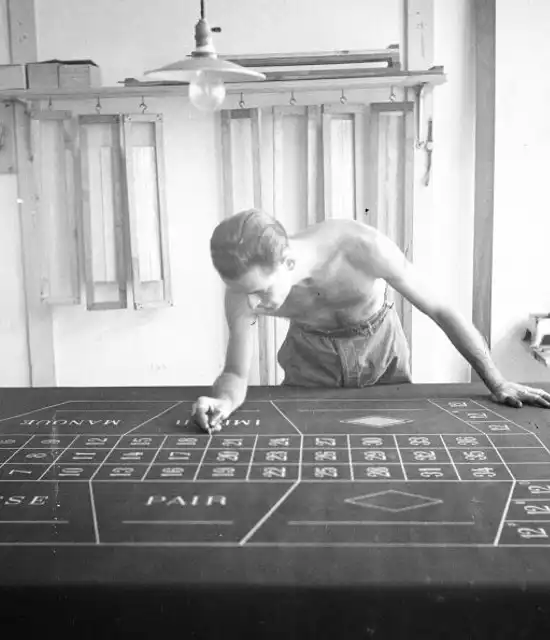

In 1863, following an ordonnance issued by Prince Charles III of Monaco, François Blanc embarked on a colossal project to build a casino on the hill in Monte-Carlo. The new Casino de Monte-Carlo and the Casino du Café de Paris soon attracted players from all over the world, but their operation required a dedicated technical department, their Games Workshops. This temple of excellence was located at the Casino de Monte-Carlo, then moved to the Fontvieille district in 1975. Artisans, who were experts in carpentry, cabinetwork, mechanics and fabrics, were specially selected to join Société des Bains de Mer, each one working in a specific workshop. Today, all these areas of expertise are located in one workshop, in another district of Monaco. Our artisans continue the traditions of the past while also using new methods as they work leather or make the stencils required to print the baize cover for a gaming table.

Did you know?

You must be 18 or over to go to casinos in Monaco. However, Monaco residents and Monte-Carlo Société des Bains de Mer employees are also excluded and not allowed to play there! A rule that has been in place since the reign of Charles III to avoid risk and disputes.

# Only in Monaco

The Casino de Monte-Carlo and the Casino du Café de Paris are the only casinos in the world to have in-house the expertise required for the conservation, maintenance and replacement of games materials. Whether for tables, baize table covers or croupiers’ rakes, today’s Games Workshops proudly continue this tradition. So much so that they are sometimes approached by foreign casinos to provide baize for gaming tables. But they have to say no, as the services of Jérôme Tachoires’ team are entirely dedicated to the casinos in the Monte-Carlo Société des Bains de Mer group. However, our artisans do have the opportunity to handle other special requests. Jérôme Tachoires tells us: “We sometimes make games cases from varnished mahogany, individually numbered and with an engraved gold plaque, for loyal customers of the casino or Resort. Or the cups given as prizes at the Festival des Étoilés, the Formula One Grand Prix de Monaco or other big Monaco events.”

Between art and craftsmanship: expertise serving our Resort

At Monte-Carlo Société des Bains de Mer establishments, there are many artisans working behind the scenes to ensure we give our guests the best possible welcome. From carpenters and the specialists making baize table covers to gardeners and clothes makers, experienced craftspeople display their talents across our locations. Team spirit is a must in the Games Workshops, where transmission of this expertise is essential. The workshops are a school of excellence where young apprentices can train in these exciting but demanding professions.

# Totems and emblems of the Casino de Monte-Carlo and Casino Café de Paris

Sharp-eyed aficionados may have noticed that certain details are different at the Casino de Monte-Carlo and at the Casino du Café de Paris to what you find elsewhere around the world. For example, the cylinders on the roulette tables are unique. They look the same today as they did in 1863, and are still maintained and repaired in the Games Workshops, as well as undergoing daily checks, out on the casino tables. On every European gaming table, 6 croupiers’ rakes are available, for use by players and staff. Each one is made in the Games Workshops from beech that is turned, stained and varnished. The numbers on the roulette tables are also made in Monaco using artisanal methods. Jérôme Tachoires says: “The black numbers are in ebony, the light numbers in rosewood.” The zero is made from palisander. Assembling and varnishing the numbers is a continual challenge for the carpenters.

# The numbers on the baize

Year-round the team is ready and waiting to step in and ensure that our Casino's customers have the best possible experience. For example, the cylinders on the roulette tables are carefully checked each day, to be repaired at the slightest sign of weakness. “That could happen once a year or after just 10 days of use,” explains Jérôme Tachoires. And what about the baize table covers? “We make and install 100 of them each year,” he continues, then playfully adds: “We like it when they are worn out, it means they have been useful!” At the Casino de Monte-Carlo, each baize table cover is printed by hand using a traditional, artisanal method that has been passed down through the generations. Nitric acid is used to fade this green fabric in the desired place, marking out features and figures, by using stencils that are also made on site. This is done entirely by hand, requiring great precision, and gives the casino tables their unique character. It requires between 10 and 15 hours to fade the fabric, about 2 hours to embroider the famous red diamond, and then the time required to fix it to the table. Which must be done to the millimetre, of course.

An unlucky number…

More and more Chinese players are coming through the doors of our Casinos. For many of them, 4 is considered to be an unlucky number. So, to reassure our Chinese clientele, the team in the Games Workshop have left the number off some of the table covers for Punto Banco, a game that is particularly popular with Chinese visitors!

# The cream of suppliers

Several materials, including the marble for roulette and baize for a table cover, are ordered from suppliers, partners we have worked with for a long time and who are known for the quality of their work. Bull-calf leather comes from the Carriat tannery, while lambskin is provided by the Richard tawery. As for the chips and plaques, for a long time they have been made by Bourgogne & Grasset, near Mâcon. This company, located in Burgundy, has kept a copy of each chip it has created for the Casino de Monte-Carlo and the Casino du Café de Paris since they were first used. Today, the chips are made from cellulose acetate and different materials are inserted to make them unique and impossible to forge.

You might also like…

Easter egg hunts: chocolate treasures to share with the family

Embrace the return of milder spring days, where every ray of sunshine promises moments of pure happiness as a family. A day where the sweet thrill of chocolate meets the excitement of shared laughter, with children and adults alike enjoying an adventure that’s full of surprises. From playful egg hunts to gourmet lunches, our hotels invite you to create a host of precious memories with your children.

AI and tourism: a new invitation to travel

Discover how artificial intelligence is reinventing the art of travel: more seamless, more personal, more vibrant. Welcome to the era of augmented tourism.

Rolex Monte-Carlo Masters, the holy ground

Learn the history of one of the most prestigious tennis tournaments of the ATP tour, the Rolex Monte-Carlo Masters. It takes place every spring on the clay courts of Monaco.