Updated on April 25, 2023

FlexSea was founded by two locals: Carlo Fedeli and Thibaut Monfort-Micheo, who had a brilliant idea: to replace plastic packaging with a biomaterial derived from seaweed. Their innovative solution uses environmentally friendly materials, while avoiding the ecological problems associated with the production of traditional bioplastics.

A bioplastic made from powdered red seaweed and natural, edible additives

Carlo Fedeli and Thibaut Monfort-Micheo, who both grew up in Monaco, have invented a bioplastic made from powdered red seaweed and natural, edible additives! Fedeli and Monfort-Micheo met at Imperial College London while respectively studying innovation and entrepreneurship and material engineering and science, and clicked in 2020 during the Covid-19 lockdown. Soon afterwards they launched their company, FlexSea, in the UK, and will shortly be setting up in the Principality. So how did they come up with the idea? They were frustrated with the overuse of plastic packaging and particularly with the over-packaging of groceries for home delivery. The two graduates, then aged 23 and 21, called each other. Carlo convinced Thibaut that they absolutely had to find a solution to the plastic pollution impacting the environment, and started working on a prototype on his balcony in Monaco.

Picture: Carlo Fedeli, at the Cambridge Cleantech Venture Day in London in January 2023.

Every year around 12.7 million tonnes of plastic ends up in the oceans or in open landfills, and each of us ingests a credit card’s worth of microplastics every month, which causes health issues such as infertility. “We wanted to find a natural material that could easily degrade in the earth or oceans,” explains Monfort-Micheo.Bioplastics have been around for a long time but still only represent a tiny proportion of global production today. So what’s the problem? “Some bioplastics are made from potatoes, sugar cane or beetroot, which have to be grown on arable land with the use of fertilizers and water. Plus, these materials only degrade in compost that’s heated to more than 58°C.”

Picture: Thibaut Monfort-Micheo, during the second conference of the “Monaco Finance Durable” Initiative in January 2023.

This red seaweed currently represents a production volume of 20 million tonnes per year, 90% in Asia with other locations in Africa (Tanzania, Zambia and Morocco) and Latin America. Why isn’t it grown on our Mediterranean coast?

Attracting interest from manufacturers

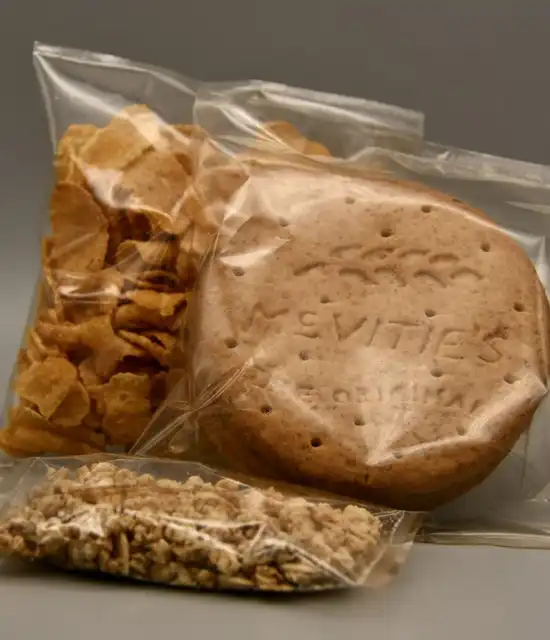

The two Monegasques designed an alternative solution: a plastic film derived from edible red seaweed that dissolves in water after 8 to 12 weeks, and can be assimilated by marine wildlife. Although it is not suitable for water-based products, this bioplastic has many other applications, for example for bags of nails and envelope windows. “We have also worked on another patent to make granules by extrusion so that we can stick to the standard production processes used by the plastics industry. Plastic products are often made in this way to create film or hard plastics such as containers for cosmetic products, hangers, clothing labels, etc.,” explains Monfort-Micheo, who has been targeting the sector’s industrial processors and packagers and is making multiple return trips between London and Monaco to achieve his fundraising goal of £2 million. “We aim to start production before the end of 2023. It should amount to 100 kg per day.” Potential manufacturing partners include giants such as P&G, Ferrero and DS Smith, as well as a number of SMEs.

FlexSea has also recently joined a business accelerator connected with the food industry, Relish Works in Chicago, which will provide a gateway to the US market. Monfort-Micheo is aware of the constraints associated with this emerging sector, in particular the cost of raw materials: “Three years ago a tonne of seaweed cost $750, whereas this year the price has risen to $3,200! So we’re working to recover waste from the industry, and we’re also looking into using different varieties that are less expensive. It’s something he really believes in: “The market for packaging, proteins and fertilizers is very promising, and is estimated to be worth between $36–$51 million in 2023."

You might also like…

AI and tourism: a new invitation to travel

Discover how artificial intelligence is reinventing the art of travel: more seamless, more personal, more vibrant. Welcome to the era of augmented tourism.

Rolex Monte-Carlo Masters, the holy ground

Learn the history of one of the most prestigious tennis tournaments of the ATP tour, the Rolex Monte-Carlo Masters. It takes place every spring on the clay courts of Monaco.

When the Monte-Carlo Société des Bains de Mer universe meets the art of Chynoax

Through its partnership with Chynoax, the Resort confirms its attachment to the French Riviera while highlighting a unique artistic vision.